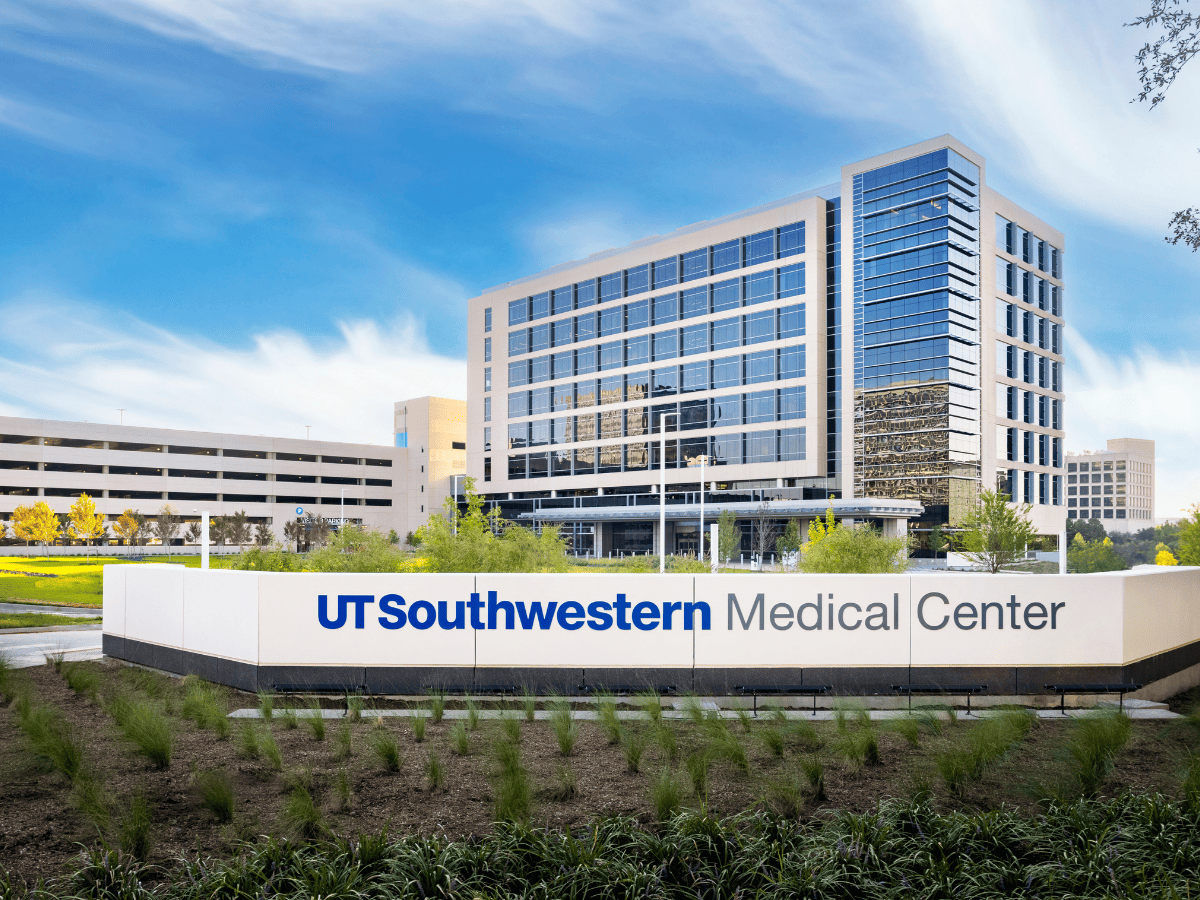

UTSW Brain Institute and Cancer Center

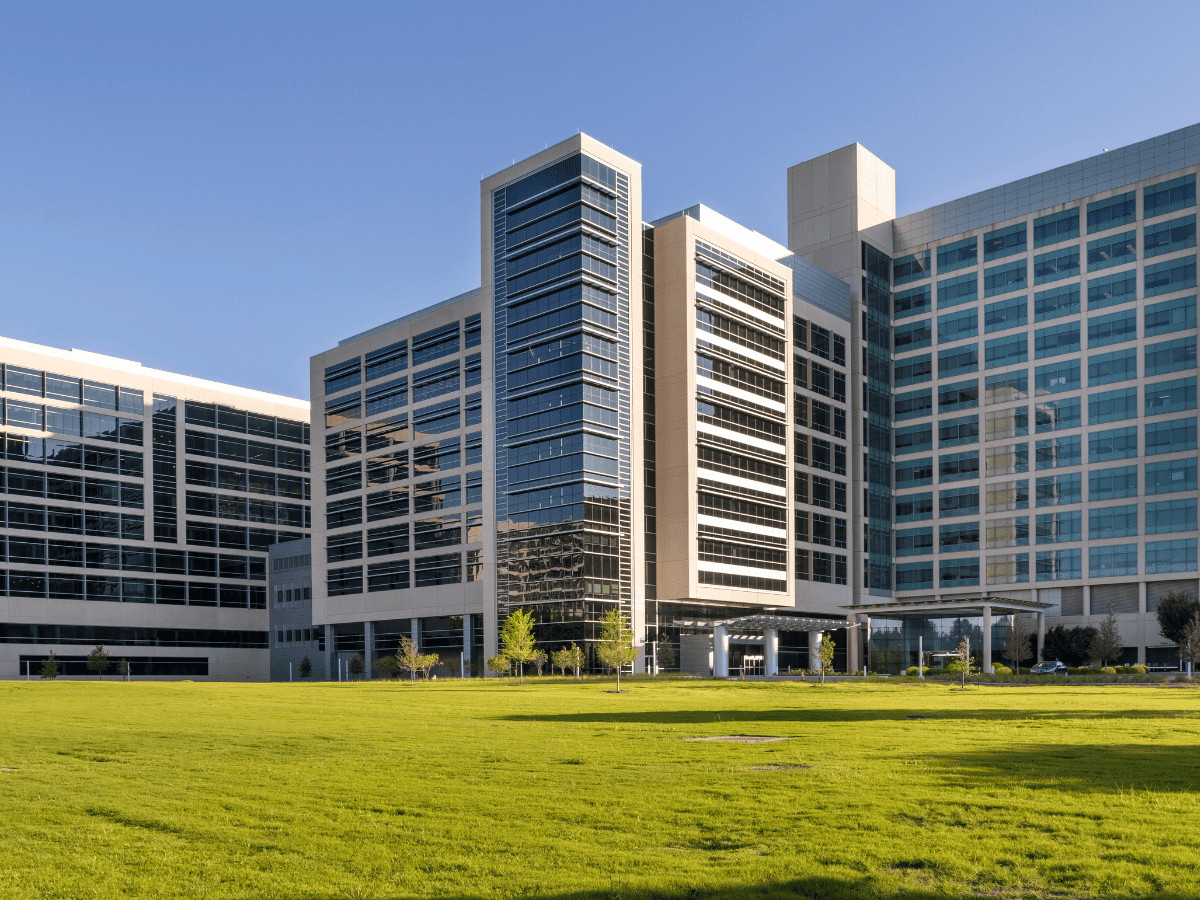

(DALLAS, TEXAS) – The UT-Southwestern (UTSW) Harold C. Simmons Comprehensive Cancer Center and Peter O’Donnell Jr. Brain Institute opened their doors to patients on November 1st, 2022, marking the conclusion of more than three years of construction. The new state-of-the-art medical facilities will have a positive, lasting effect on millions of Americans suffering from brain disease. Furthermore, this project tripled UTSW’s current cancer care capabilities, leaving additional space to pursue research, make discoveries, and collaborate to improve treatment and find a cure.

In June 2019, Vaughn Construction hired Brandt to perform the design-assist mechanical and plumbing installations on the two nine-story buildings, approximately 300,000 square feet each. In addition, our team worked throughout the utility tunnel, parking garage, and a new central utility plant (CUP). Furthermore, Brandt renovated an existing CUP to accommodate the new campus expansions.

PROJECT HIGHLIGHTS

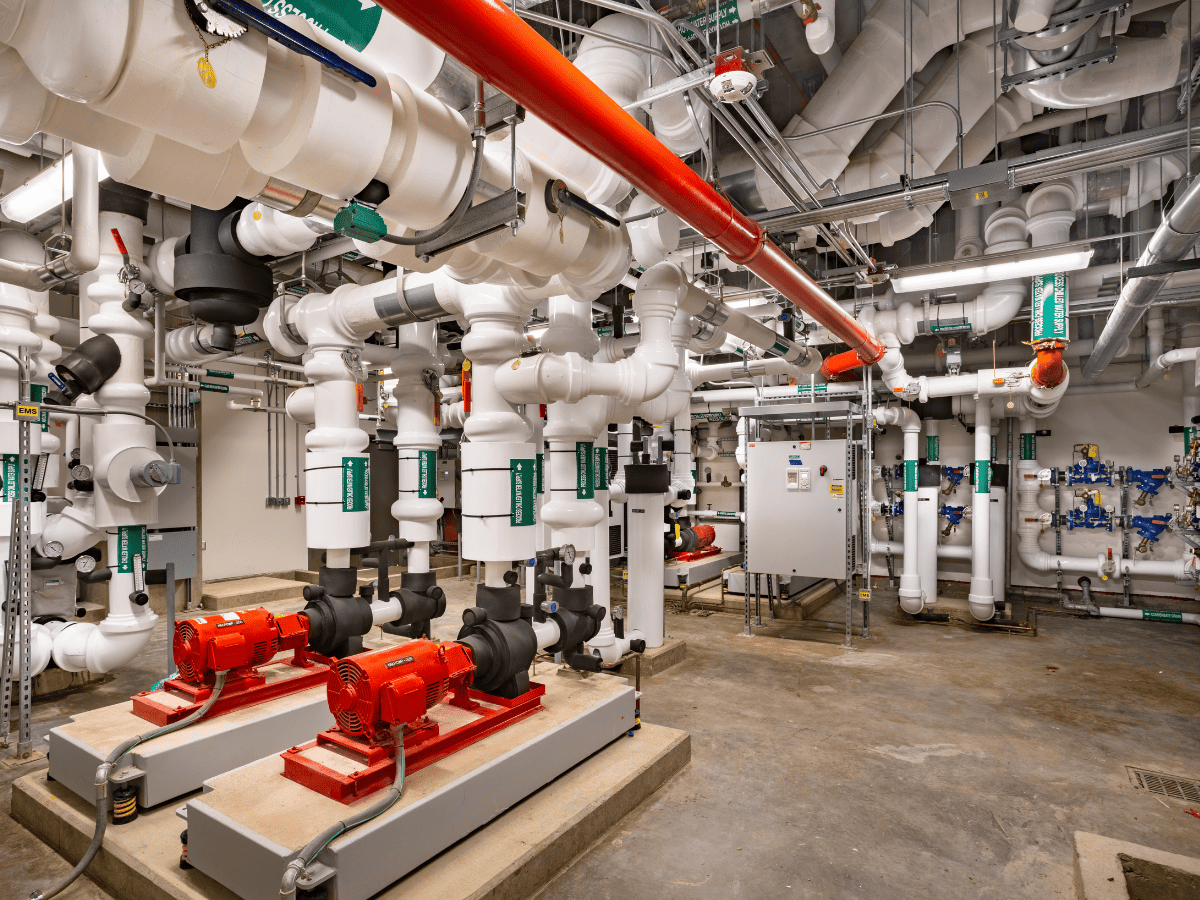

Installations included:

- 989,142 pounds of sheet metal installed

- 37 fans with a combined 598,580 cubic feet per minute (CFM) output

- 14 custom air handling units with a combined 1,015,000 CFM output

- 46 mechanical and plumbing pumps with a combined flow of 16,219 gallons per minute (GPM)

- 91 fan coil units

EARLY PROJECT INVOLVEMENT

Early project involvement enabled our team to identify opportunities to maximize productivity and opportunities for fabrication. Collaboration across the organization between BIM, operations, the North Texas fabrication shops, tools and logistics, QA/QC, and purchasing allowed Brandt to develop and execute a highly efficient plan.

In renovating an existing central utility plant (CUP) to support the campus’ massive expansions, the utilization of our in-house construction technology offerings saved time and energy in finding unique solutions to the problem at hand. A Matterport scanner enabled our team to overlay the real-life imaging over our 3D model to determine how to fit a 3,000-ton chiller in a place that initially housed an 800-ton chiller. This allowed all required clearances to be considered, and we successfully upgraded the chiller plant’s capacity without having to perform much re-work of the existing space. Furthermore, this upgrade will allow for future expansion beyond this project. Additionally, performing the necessary shutdowns and tie-ins for the existing chilled water system in a timely manner was crucial to following the project schedule.

FABRICATION

- A 24-inch chilled water pipe

- A two-inch high pressure steam condensate pipe

- A one-inch high-pressure steam pipe

- A four-inch pumped steam condensate pipe

In coordination with Vaughn Construction and an overhead crane service, we placed the fabricated steel pipe racks into the underground utility tunnel. Fabricating most piping and rack systems in a controlled environment streamlined onsite installation and reduced field hours, enabling us to set approximately 30 feet of racked piping at a time. The utility tunnel consisted of 97 racks which hold about 2,800 linear feet of piping.

In 2023, Brandt received a TEXO Distinguished Building Award for our involvement in this project.

PROJECT TEAM

- Owner: UT Southwestern

- Architect: EYP Architecture & Engineering

- Engineer: Affiliated Engineers Incorporated

- Contractor: Vaughn Construction

PROJECT DETAILS

- Start/Completion Dates: 12/2018 – 02/2022

- Project Size: 600,000 SF

- Brandt Role: Design-Assist Mechanical and Plumbing Services