Understanding Industrial Refrigeration Systems

Businesses that need to cool products and goods on a large scale use industrial refrigeration systems. The goal of industrial refrigeration is to keep goods at an optimal temperature in an efficient, cost-effective way. Learn how industrial refrigeration systems work and how Brandt can optimize your company’s cooling process.

Industrial Refrigeration System Explained

Since the mid-nineteenth century, the food and beverage industry has used industrial refrigeration systems to keep large quantities of products cold or frozen. Over the years, refrigerant systems have become popular in data centers, manufacturing plants, and even ice rinks because they provide quick, efficient cooling in expansive areas.

The basic concept of refrigeration systems is that they move heat from one area to another. The actual process is quite complex and requires many components to keep the refrigeration cycle in working order.

Industrial Refrigeration System: How it Works

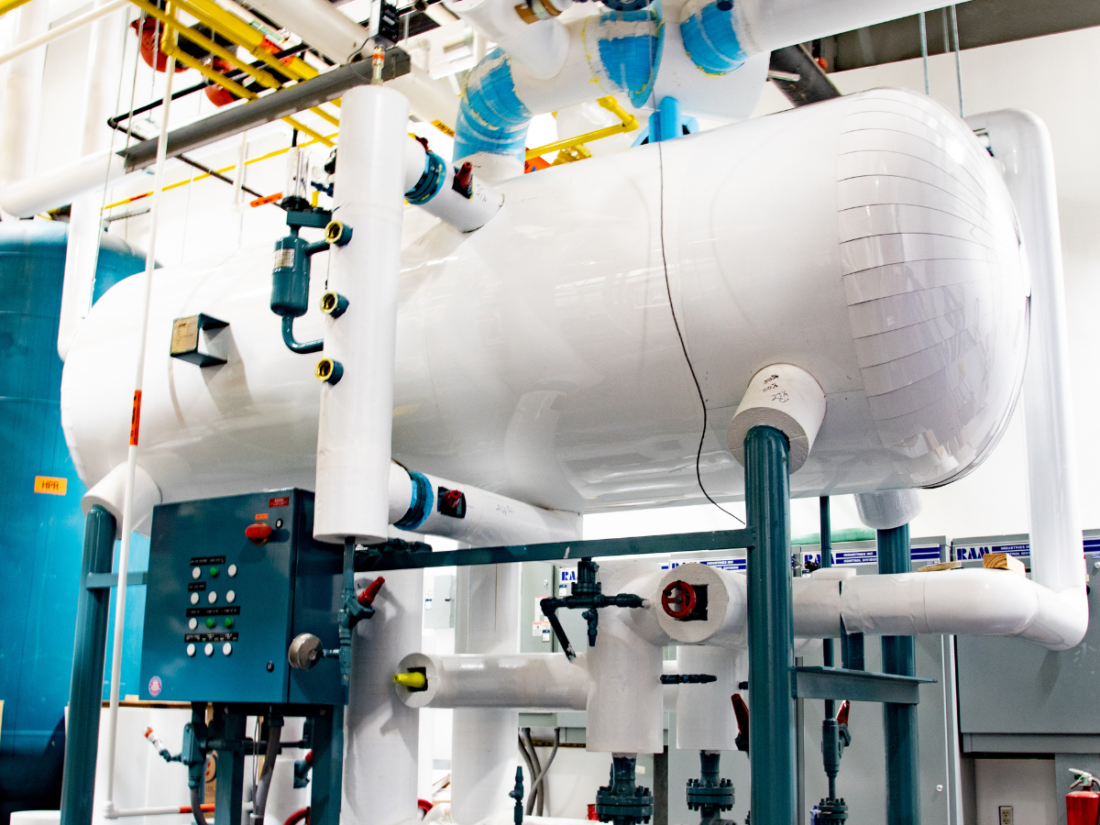

Industrial cooling systems work by removing heat from an object and transferring it elsewhere using refrigerants. Refrigerants change from a gas to a liquid state during the refrigeration process, pulling heat from the refrigerated area and expelling it outside. There are a few main components of an industrial refrigerator that complete the cycle:

- Metering device: To start the industrial refrigeration process, the metering device, often an expansion valve, releases liquid refrigerant into the low-pressure part of the cycle, where it expands and vaporizes.

- Evaporator: In the evaporator component, the refrigerant enters and moves through the refrigerated space, pulling heat from items by evaporating into a vapor. The resulting vapor is cold and low in pressure.

- Compressor: After the refrigerant makes its way through the evaporator, it gets pulled into the compressor component, which compacts the vapor. At this stage, the vapor is highly pressurized and very hot.

- Condenser: The condenser uses cold air or water to rapidly cool the refrigerant, turning it back into a liquid. The excess heat is released, and the refrigerant is transferred back to the metering device to start the cycle again.

Industrial refrigerators use these four basic components in a variety of ways to create a customized cooling solution for your business. You can choose between refrigerant options and decide if an air- or water-cooled condenser is the best fit for your needs. Brandt offers custom refrigeration solutions to optimize your company’s food processing, manufacturing, and beverage production processes, and we specialize in ammonia refrigeration systems.

Ammonia is one of the most popular, efficient, and cost-effective refrigerants in industrial refrigeration. Since the dawn of industrial refrigerators, businesses have used ammonia as a refrigerant due to its affordability and quick cooling capabilities.

Ammonia Refrigeration System Basics

Like other industrial refrigeration systems, ammonia systems use pressure and temperature changes to pull heat from items. The benefit of ammonia is that it’s much colder than room temperature in its compressed form, allowing it to cool things at a fast rate. There are multiple types of ammonia refrigeration systems that work in a variety of settings.

Aside from its efficiency, ammonia is popular because it’s affordable, environmentally friendly, and odorous when released into the air. Ammonia is readily available and far cheaper than hydrofluorocarbons (HFCs) and freon, two other industrial refrigerant options. Plus, it works faster than the other two, making it the most affordable industrial refrigerant.

Though ammonia produces toxic fumes when released into the air, it doesn’t harm the ozone layer when it reaches the atmosphere. If you are looking for an environmentally friendly refrigerant option, ammonia is the clear winner. Additionally, ammonia produces a strong odor when it leaks, allowing workers to evacuate the area before being exposed to harmful concentrations of the gas.

Streamline Your Refrigeration Process With Brandt

If your business is ready to install an industrial refrigeration system, our team of experienced, licensed refrigeration experts is prepared to help. Whether you need assistance with engineering, installation, maintenance, energy efficiency, or all four, Brandt offers refrigeration solutions for any business. We design ammonia and freon systems with your needs in mind, and we ensure compliance with Environmental Protection Agency regulations during installation.

At Brandt, we understand that refrigeration problems can snowball into much more significant issues for your business. That’s why we’re available 24 hours a day to come to your business and address problems. We also provide remote monitoring services that prevent issues and outline proper maintenance techniques, so your employees can stop problems before they occur.

Contact Brandt today to learn more about how we can help your business through industrial refrigeration design, installation, and maintenance.