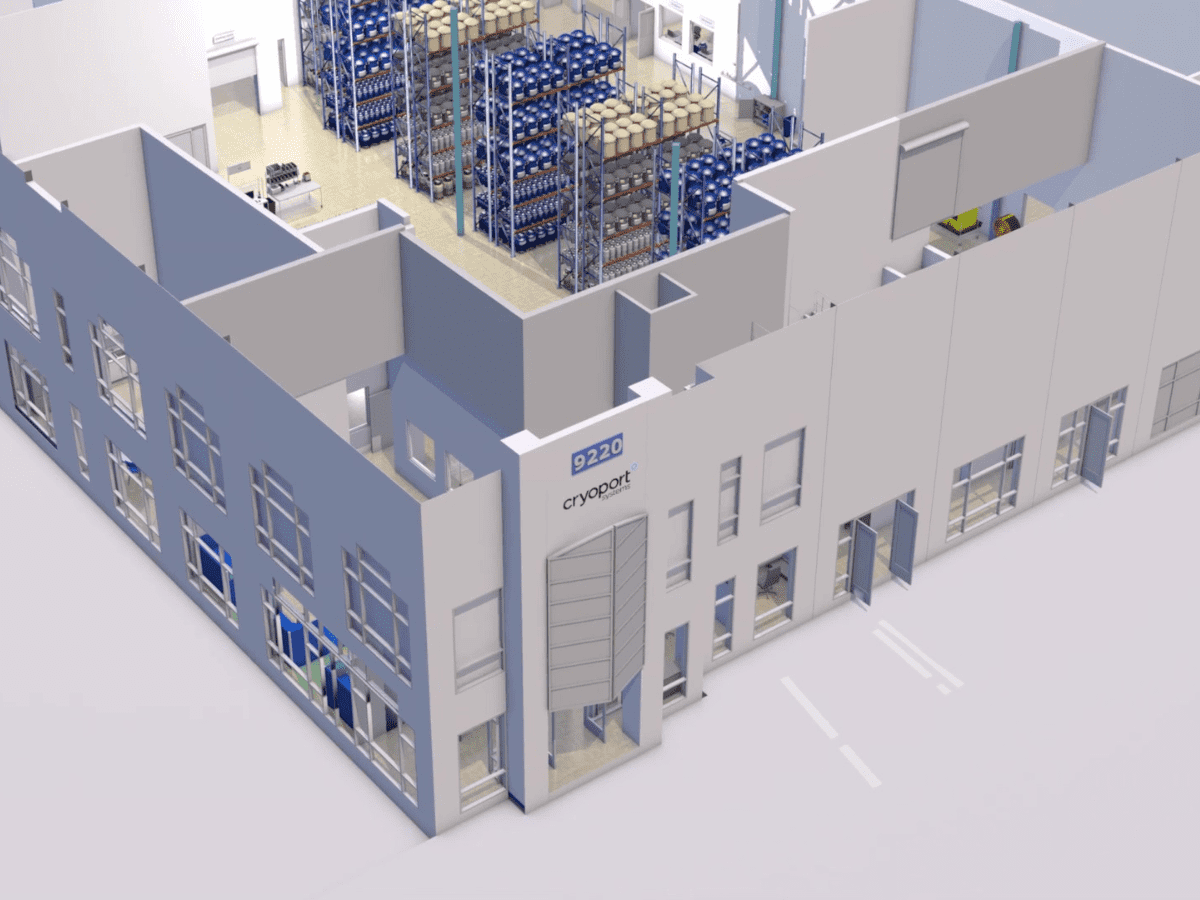

Biopharmaceuticals and Research Facilities

Brandt’s expertise in biopharmaceutical and research facilities encompasses a wide range of services tailored to meet the unique needs of these dynamic industries. From state-of-the-art manufacturing facilities to cutting-edge research laboratories, Brandt delivers innovative solutions that optimize efficiency, reliability, and compliance. With a focus on quality, precision, and safety, we partner with biopharmaceutical companies and research organizations to drive advancements in healthcare, biotechnology, and pharmaceuticals.